![]() +1 929-458-6213

+1 929-458-6213

Managing STL files is essential for efficient 3D printing. It slows down the slicing process, makes sharing harder, and eats up storage. The only to reduce these hassles is to reduce the stl file sizes. Below, I have demonstrated how to reduce STL file sizes while keeping everything functional practically.

Table of Contents

ToggleWhy Reduce STL File Size?

Big STL files are a hassle. They can slow down your slicer and sometimes crash your software. Sharing them via email or file-sharing platforms? Forget it if the file is too large. And let’s not even start on limited storage.

Making STL files smaller makes everything faster, smoother, and more efficient. Smaller files also help prevent print failures caused by unnecessary details.

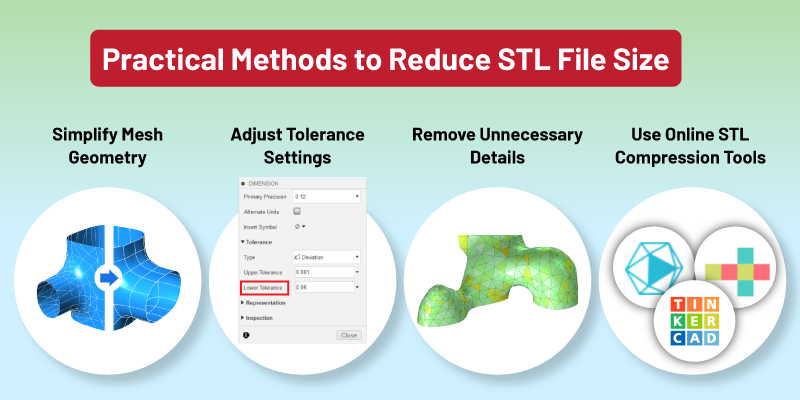

4 Practical Methods to Reduce STL File Size

You may find hundreds of tutorials and videos about reducing the STL file sizes, but not all of them are practical and effective. Here are some of the most effective methods I use:

1. Simplify Mesh Geometry

The most common reason STL files are huge? Too many polygons. Every little triangle adds to the file size. Simplifying the mesh reduces the number of these triangles. Here’s how I do it:

Blender: Import your STL file. In “Object Mode,” use the Decimate Modifier. Adjust the “Ratio” slider to reduce polygons. I’d say stick between 0.3 and 0.6 for good results. Preview changes to avoid removing too much detail.

Meshmixer: Use the “Reduce” tool. It lets you control how much detail you want to keep. Play around until the file size drops, but your model still looks good. For simpler models, even a 50% reduction works.

Fusion 360: Export with a lower mesh refinement setting during the STL export process. Look for “Low” or “Medium” detail options.

Simplifying mesh geometry is a go-to method for reducing file size while retaining essential details. You can also experiment with different tools to find what works best for your project.

2. Adjust Tolerance Settings

Most CAD software gives you control over tessellation. When exporting your model as an STL, reduce the tolerance settings. This limits the number of triangles generated. For example:

Fusion 360: Go to “Mesh Refinement” when exporting. Set it to “Custom” and reduce the tolerance or deviation.

SolidWorks: Look for the “Resolution” slider during export. Move it to “Coarse.” Adjusting these settings can significantly reduce file size while preserving overall shape.

Lowering tolerance can dramatically shrink the file size without compromising too much detail. This is an easy win if you’re working with models that don’t require high-resolution features.

3. Remove Unnecessary Details

Not every detail on your 3D model is necessary. If the part isn’t visible or functional, remove it. For example, internal supports, hidden parts, or overly complex features can go. Tools like Blender and Tinkercad make it easy to delete unnecessary sections of your model.

For example, consider a decorative model with intricate patterns. You can simplify or remove more minor details that won’t affect the final look of your print. Consider the model’s purpose and use case when deciding what to remove. Simplifying can save space and printing time.

4. Use Online STL Compression Tools

If you’re short on time or uncomfortable with software, online tools can help. I’ve tried these:

Tinkercad: Simple to use. Upload your file, make quick edits, and export a smaller version.

MakePrintable: Specializes in optimizing STL files. It’s not free, but it’s effective for large models.

3D Slash: Basic but suitable for quick compression.

These platforms often provide sliders to adjust the level of compression. Just don’t overdo it. Over-compression can lead to a blocky or distorted model, compromising the final print quality. Test the outputs to ensure they meet your needs.

Best Practices to STL Keep Quality

Reducing file size is a balancing act. Too much compression and your model looks like a pixelated mess. Here’s how I keep things clean:

Avoid Extreme Simplification: Don’t go too low on the polygon count. Always check how your model looks after changes. Models that require precision, like functional parts, deserve extra care.

Keep Backups: Save a copy of the original file before reducing it. Trust me, it’s a lifesaver.

Test Prints: Print a smaller version of your compressed file to see if it’s still functional.

If you’re exploring the balance between detail and performance, understanding the differences between low-poly and high-poly models can help.

Tools I Recommend

There are tons of options for reducing STL file size. Here are my go-to tools:

- Blender, Free, and powerful. It takes time to learn but offers complete control over mesh geometry.

- Meshmixer, Easy to use and focused on 3D printing needs.

- Fusion 360, Great for CAD-based workflows and exporting optimized STL files.

- Tinkercad is perfect for beginners.

Each tool has its strengths. Pick one based on your expertise and project requirements. Try experimenting with different features to find the best solution for your needs.

How to Test Smaller STL Files

After reducing your STL file size, you’ll want to test it. Here’s my process:

Run an STL Repair: Use tools like Netfabb or Meshmixer to check for errors. These tools identify and fix broken meshes.

Inspect the File: Open the reduced STL in your slicer software. Zoom in and rotate the model to ensure it looks good. Pay attention to any missing or distorted sections.

Test Print: Print a small version to ensure there are no surprises. Start with a draft-quality print to save material.

Testing is crucial to ensure the reduced file is functional and maintains the desired quality.

Conclusion

Reducing STL file sizes doesn’t have to be complicated. You can make your files smaller without losing detail by simplifying the mesh, adjusting settings, and using the right tools. Always remember to save a backup and test your reduced files before printing. It’ll save you headaches and time in the long run.

Related Posts